Hypnotiq

I - AM - HYPNOTIQ

- Messages

- 1,553

- Location

- Lake in the hills, IL

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

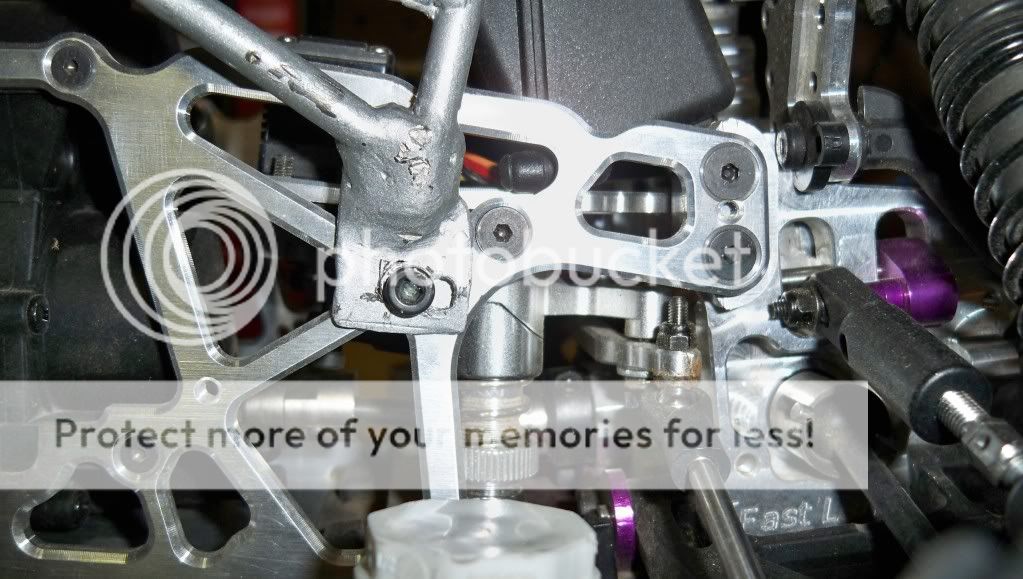

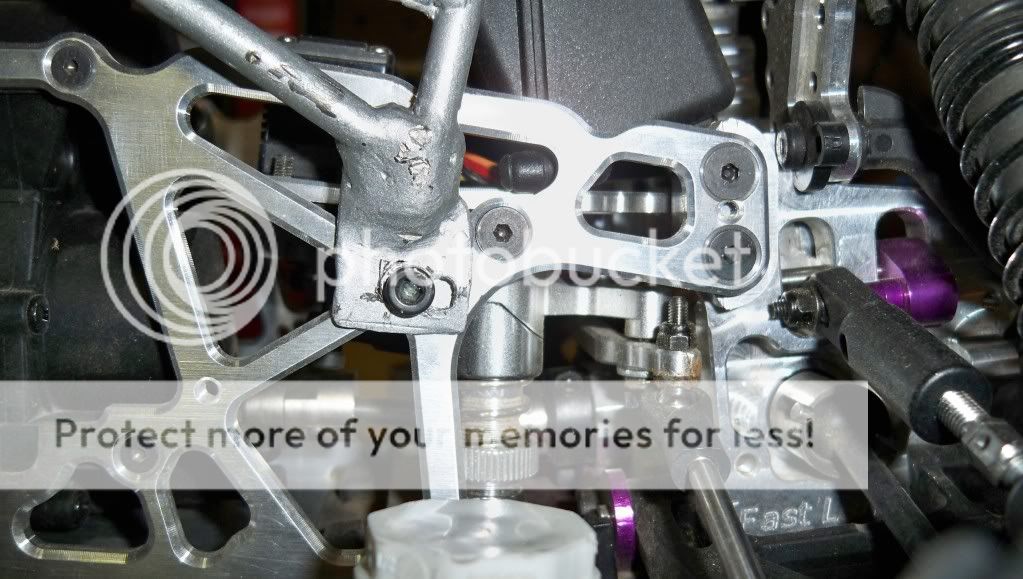

i noticed that the plate that the steering servo BENT the plate its attached too. so i will have to brace that up i think.

Slap ... the Back of the plate has no brace to the tvp. From the pic I see its free from the bell crank back to move on impact how many time you bounce it of the cage duc?someone help me understand how a servo is capable of doing this without being destroyed :dunno:

wow ................

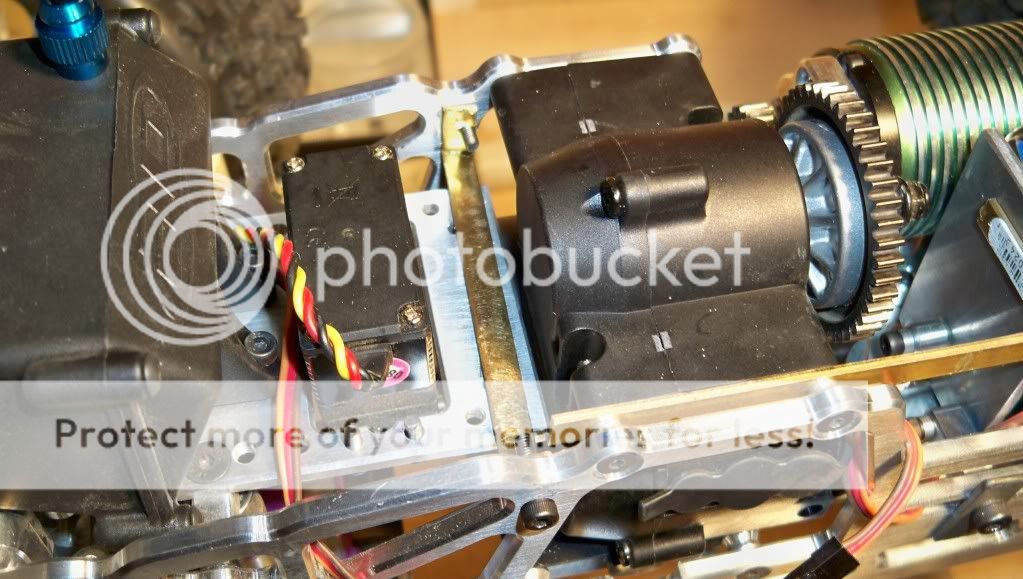

i called castle today. after telling them what happened they are sending me a new one! YAY! the tech department there are super nice to deal with. we BS'd most of the time. great folks

Welcome to HPISavageForum, a friendly forum to discuss the Savage RC Truck.

Your voice is missing! You will need to register to get access to the following site features:We hope to see you as a part of our community soon!