J1A1H

Well-Known Member

- Messages

- 967

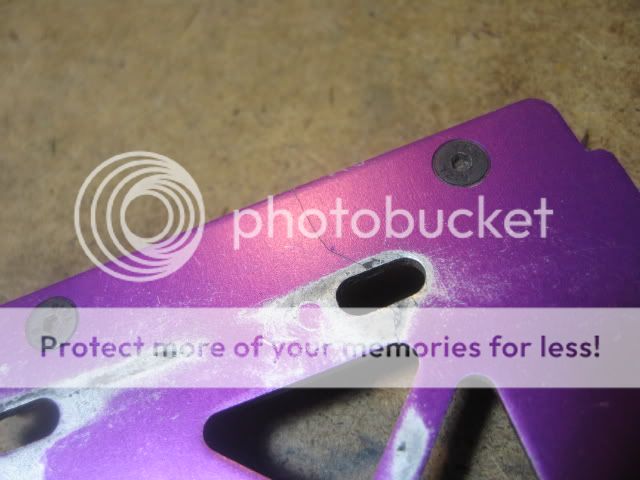

i have just torn my truck completely down, and all my bearings are shot... one of my diff bearings had completely seized! I thnk a boca bearing upgrade is going to be coming sooner than expected! I am going to place a small shim either side of every bearing if possible to prevent any damage to them. I noticed that my stock bearings were getting "pinched" in areas allowing dust to get in...