2StrokesFTW

Well-Known Member

- Messages

- 224

hey guys, well most of you know that the savages x4.6 roto starter's small cylinder and springs got sucked into the motor. I took the back plate off, i got the two little springs out as well as the very small cylinder that goes in the bottom of the rod. I installed them, and everything is working fine. I put the motor back together, and installed it back in the chassis. To check the motor would start, i went outside and started the motor up. The motor had no gears connected to the wheels, and no load on it. I let it idle and revved it a bit and the clutch came apart. I went inside and put the clutch back together, and it seems to work fine. I went outside again with everything in place and tight, and started the truck up. It started right away, but the wheels are spinning fast. I let it warm up like that on a stool. After that i put it on the ground and the car was moving around even though i wasnt giving it throttle. When i would apply the brake, the motor would immideatly shut off. I put all the needles to factory settings and same thing would happen. I adjusted the throttle trim to neutral and that didnt do anything. I adjusted the idle to give it more gas and slow the motor down and still nothing would happen, wheels were still spinning fast. With all the needles at stock setting it took it for a ride, came back and still the same thing would happen. What is wrong with it?? I took some pictures of the linkage and all else. Can you guys help me. I know its alot to read but you gotta read it all to understand my situation.

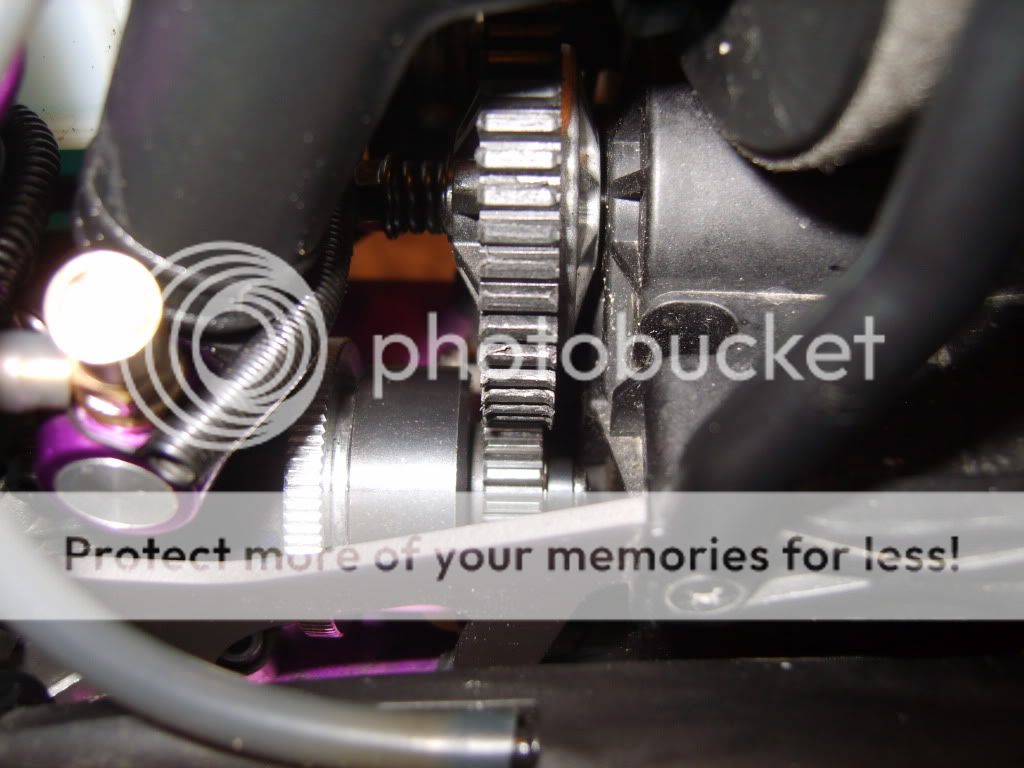

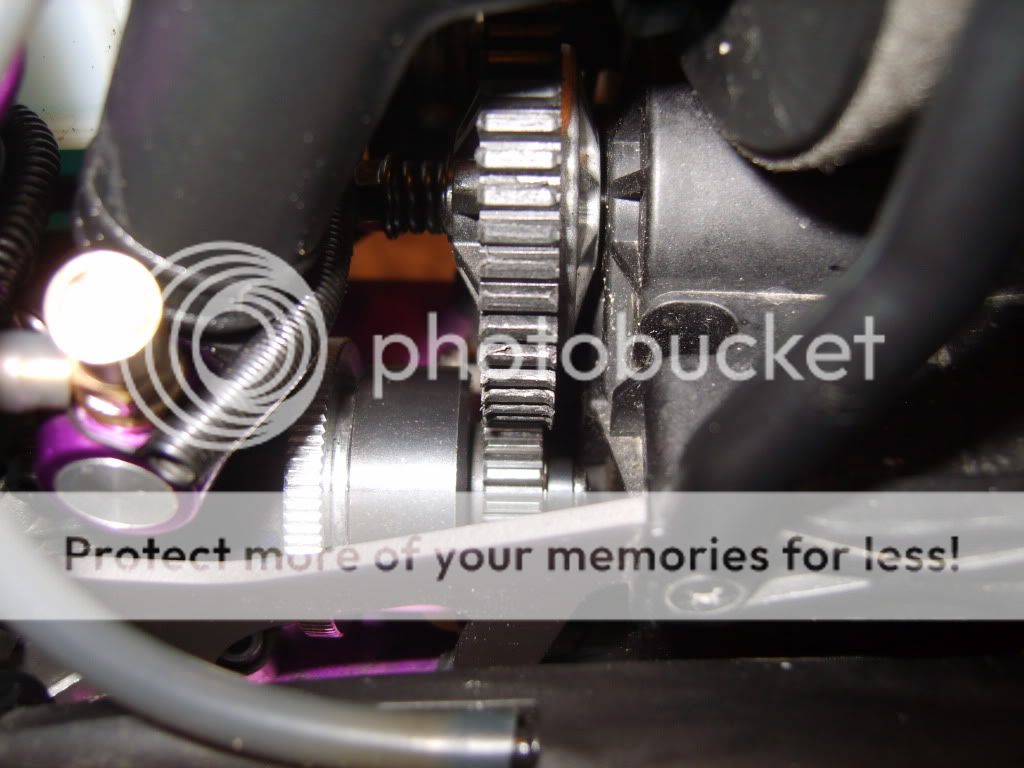

gears are meshing properly like in the manual

Slide has a 1mm spacing

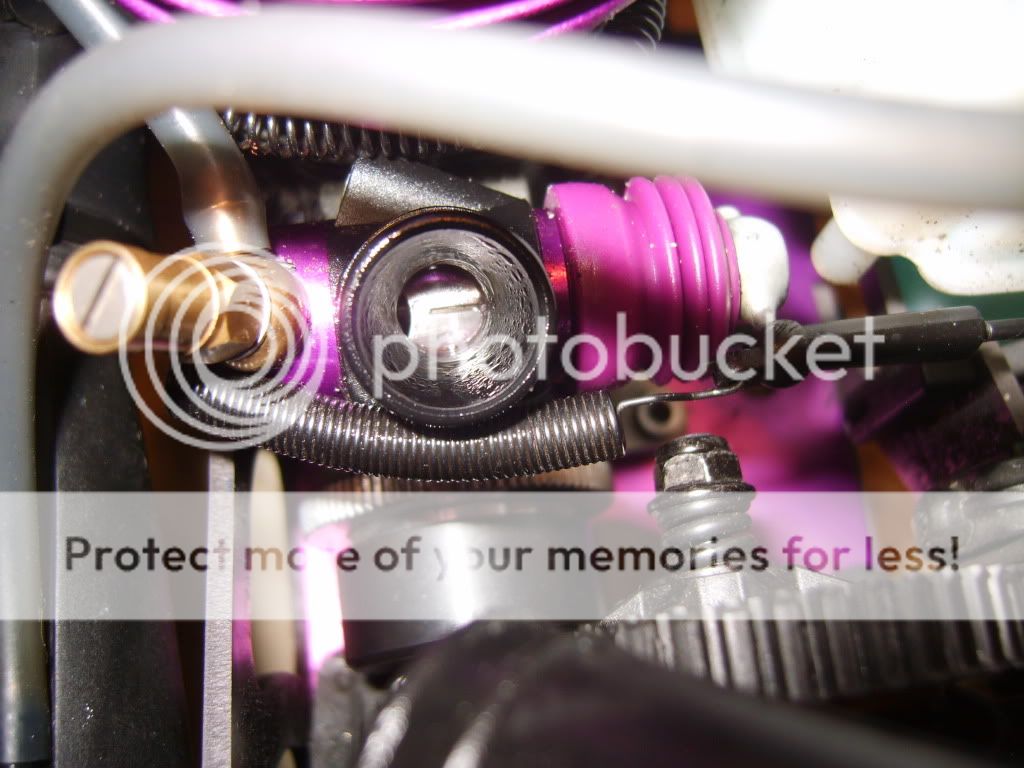

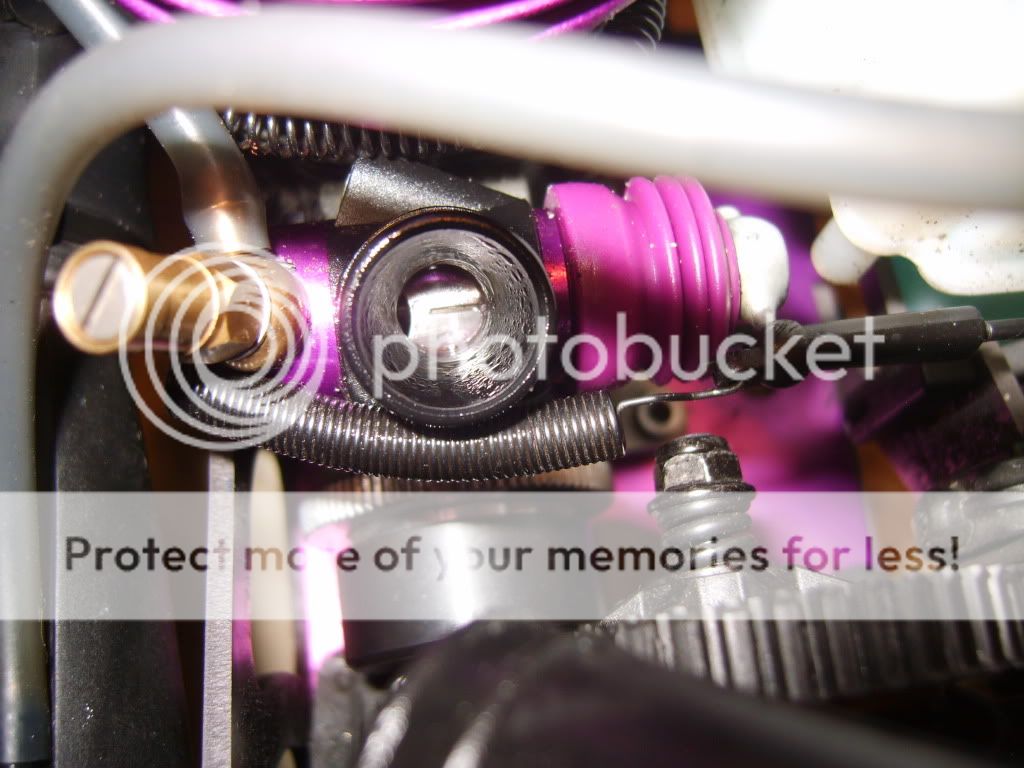

LInkage

closer look at the linkage

gears are meshing properly like in the manual

Slide has a 1mm spacing

LInkage

closer look at the linkage

`

`