what the FLUX

is goin' on around here!

- Messages

- 325

- Location

- Victoria, Australia

- Thread starter

- #61

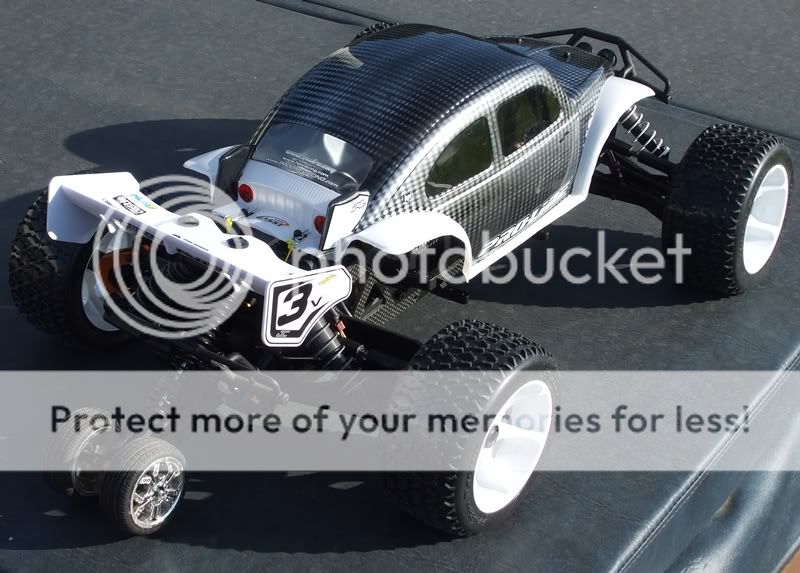

I mount the wing to the rear tower. I'm  uke: about the way the PRC wing mount mounts to the tower.

uke: about the way the PRC wing mount mounts to the tower.

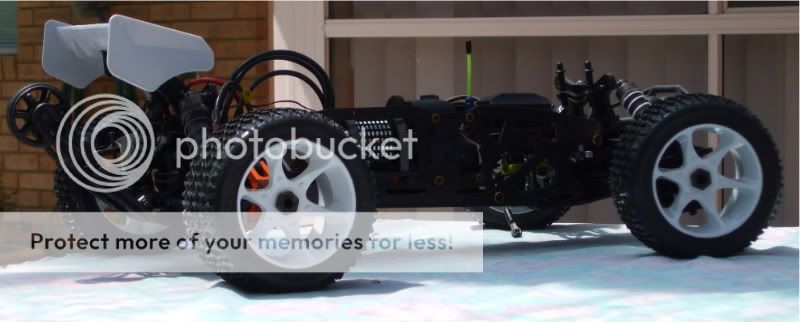

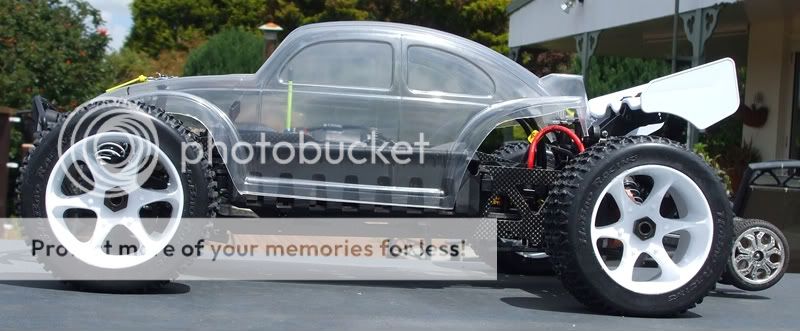

and got most of the rear put together

fitted the rear

dam it's big:rock:

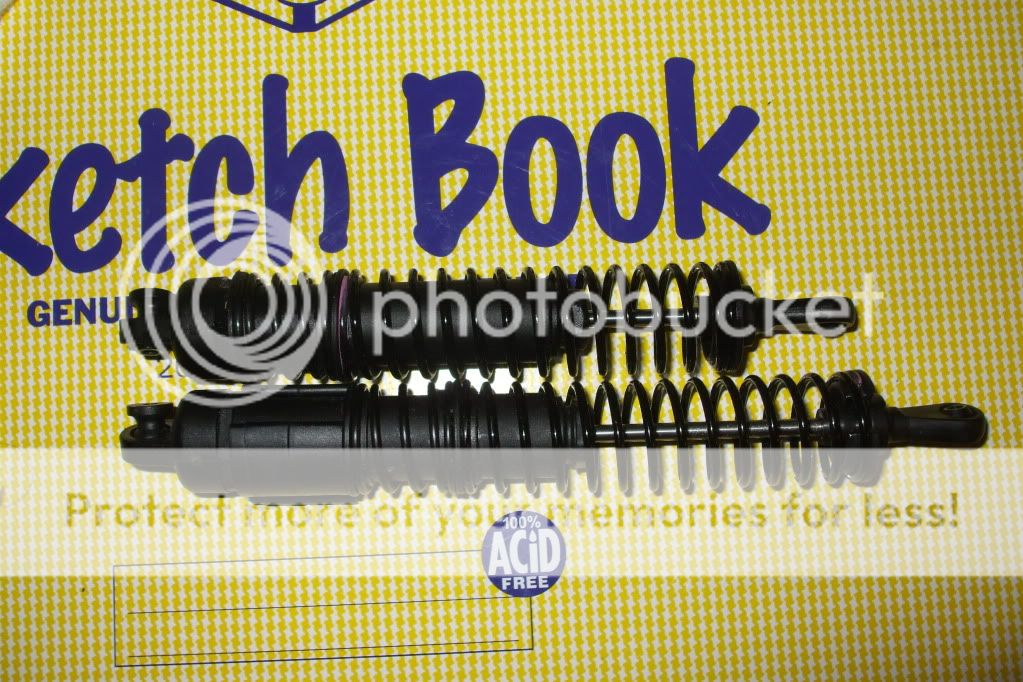

It's got no droop. I'll try softer spring. Any suggestion would be great.:thumb:

:cheers:

and got most of the rear put together

fitted the rear

dam it's big:rock:

It's got no droop. I'll try softer spring. Any suggestion would be great.:thumb:

:cheers:

I always do, thanks 88

I always do, thanks 88

what for Josh.

what for Josh.