Bankrupter

Well-Known Member

- Messages

- 4,792

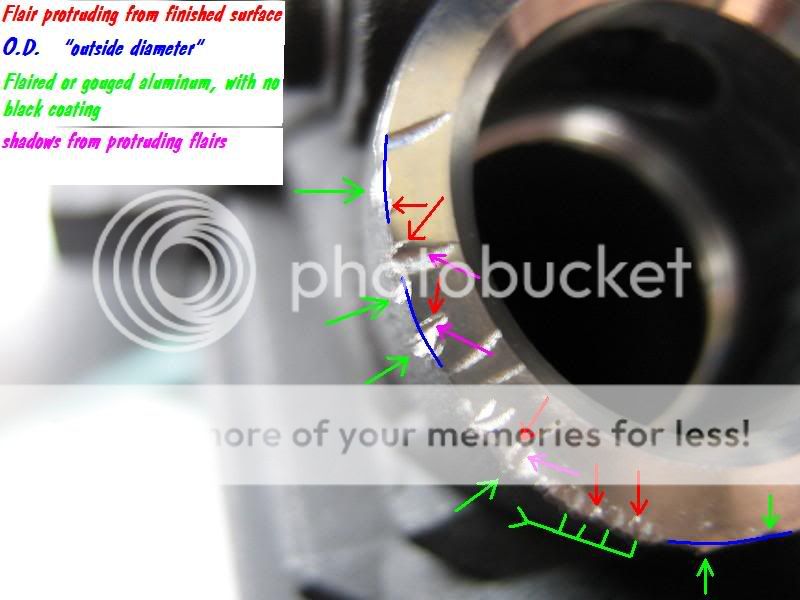

I got my picco today and look what they sent me. This is NOT a superficial scratch. I can catch it with my thumb nail and good too. This would never seal up and a noob would never know why he got a bad tune due to the HUGE air leak it will make. It goes from the outer case all the way into the crank channel as if they did it with the tool that cuts it. This type of stuff should NEVER leave the factory!!!!!!

Ill let you all know what Picco does about this! Reason # 1 to inspect all new motors before you start them.

Ill let you all know what Picco does about this! Reason # 1 to inspect all new motors before you start them.