Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Ask questions. Share your HPI Savage knowledge. Register TODAY!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clutch bell Endplay?

- Thread starter LoudTaco

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

Pineapple

Just a regular member

- Messages

- 893

- Location

- Sandy Eggo

Ditch that brass one- use a kit like this.

http://www3.towerhobbies.com/cgi-bin/wti0001p?&I=LXNT03

http://www3.towerhobbies.com/cgi-bin/wti0001p?&I=LXNT03

f1n3sse

Well-Known Member

- Messages

- 929

- Location

- philadelphia

its just a washer any will do fine if they are the same size, the kit is nice because you get spare parts if you get a second mill or have another r/c.

Put some small washers between the clutch shoes and your flywheel will let the shoes move a little freeer as they wont be right on the flywheel. This will use up a little space and make sure you use a pretty tough washer on the end right next to your screw. You also want just a little bell movement.

Bankrupter

Well-Known Member

- Messages

- 4,792

Just replace that brass color with a piece of fuel tube and your good to go!

Bankrupter

Well-Known Member

- Messages

- 4,792

yep no more shims! pita...

Chris

Well-Known Member

- Messages

- 285

- Location

- Lafayette, Louisiana

Just replace that brass color with a piece of fuel tube and your good to go!

Um...you're serious? The tubing replaces all shims *outside* of the bearing right? Use a washer with the screw to hold the fuel tube in place?

Won't the rotation fry the tubing...guess not if it spins with the bearing and clutch bell? Not too much play or give?

hmmm

Blazer X

Well-Known Member

- Messages

- 973

- Location

- Hoosierland

It's hard to tell but it looks to me like the flywheel is setting farther back on the crank than what I'm used to seeing on my engines. Therefore you have more play up front to compensate for. Make sure you have a good collet on there. Also toss that brass washer, it wears out in about half gallon and you will be have slop in the clutch again very soon. Replace with this...http://www.hpieurope.com/piw.php?lang=en&partNo=86171 I have tried the fuel tubing before and it didnt last long for me but it works for temporary fix.

Bankrupter

Well-Known Member

- Messages

- 4,792

yes exactly on all counts. I have not tried it to date but plan to run it on my new Picco thats going up to Robin for modding. Ill have Robin post his pics and stuff on this.Um...you're serious? The tubing replaces all shims *outside* of the bearing right? Use a washer with the screw to hold the fuel tube in place?

Won't the rotation fry the tubing...guess not if it spins with the bearing and clutch bell? Not too much play or give?

hmmm

Purenitro

Owner of Extreme RC Mods

- Messages

- 875

I came across this mod one day in my shop while I was looking for something to replace the brass shim. It is cheap and simple to do, just make sure that your cuts are even and the clutch bell can spin freely, your good to go. The first piece of tubing I put on years back lasted almost four gallons before I lost it, had plenty more though lol. I'm not saying that it's better then the steel shims, it's just an alternative.

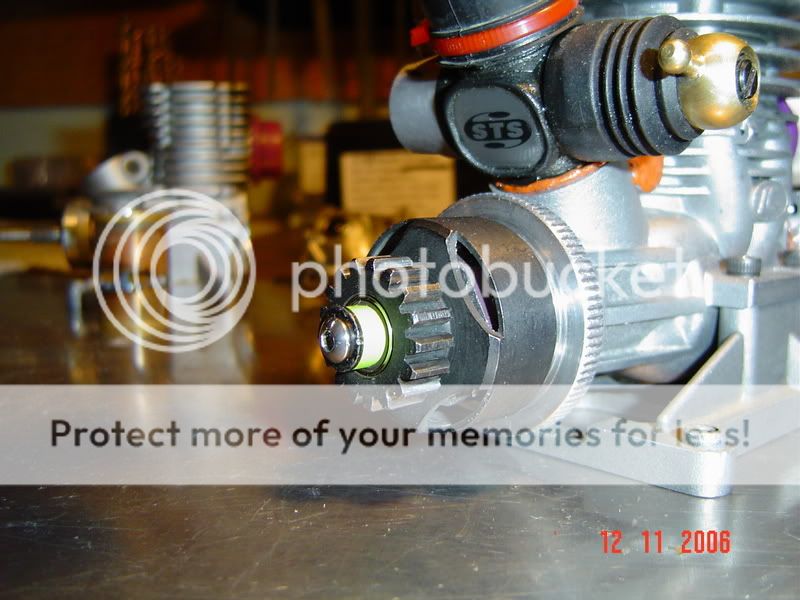

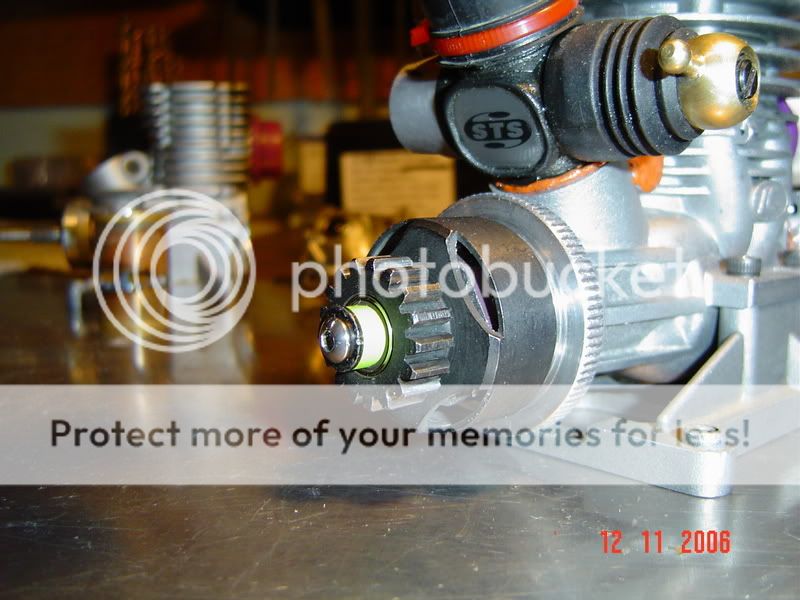

Here is a pic.

Here is a pic.

Mickey

just me

- Messages

- 3,098

- Location

- Renfrew Ontario Canada

best part about this mod is you can color co-ordinate lol

- Thread starter

- #14

It's hard to tell but it looks to me like the flywheel is setting farther back on the crank than what I'm used to seeing on my engines. Therefore you have more play up front to compensate for. Make sure you have a good collet on there. Also toss that brass washer, it wears out in about half gallon and you will be have slop in the clutch again very soon. Replace with this...http://www.hpieurope.com/piw.php?lang=en&partNo=86171 I have tried the fuel tubing before and it didnt last long for me but it works for temporary fix.

The Collet and flywheel are both brand new.