orcusomega

Well-Known Member

- Messages

- 653

- Location

- Royersford, PA

I have this in a few locations throughout the board (replies, my project builds, etc) so I thought I would put it all into one thread, and hopefully this will help someone!

Well today I started the first steps in the tank relocation, by moving the revceiver and battery to the back. This is also posted in the How-To section, but wanted to add it here too:

=======================================

OK, few caveats:

1) This is my first how-to, so be gentle

2) My truck is a Savage 25 with the XL TVP's - this gives me the room to move the battery box behind the motor - so I don't know if it will work for everyone

3) Where the battery is mounted will block your access it you use a roto-start - just keep that in mind.

So this is how I moved my receiver and battery from the front of the truck to the rear, in preparation for a mid-tank mod coming soon. My mission was to do it as cheap as I could using crap I had lying around as much as possible.

Parts List:

1) 2 aluminum bulkhead braces

2) 2 servo wire extensions

3) one T-Maxx battery box

4) one motor mount brace

5) one receiver box (Traxxas #4924 - no idea what it is out of)

To start things off, I needed to figure out how to mount a horizontal brace from TVP to TVP without drilling - I did not want to weaken the TVP at all, and it seemed there HAD to be a way to make this work.

When I lined up the brace between the TVP's, I saw that the spaces cut out where different from side to side, so I had to find a place on each side where they were the same. Once I did that, it should be a matter of putting something there to hold it in place - right?

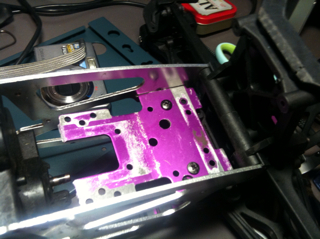

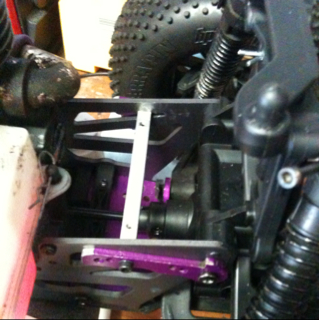

After I found a place on both sides of the TVP's where I could attach the brace and keep it even, I needed a way to keep it from moving around too much - I happened to have a few diff braces lying around from my XL diff conversion, and I used them to hold the brace in place front to rear. All put together, it looks like this:

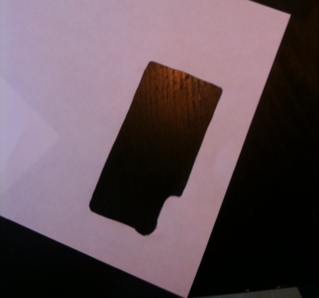

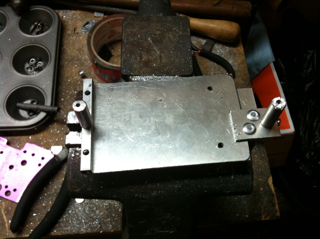

You will notice that the brace is significantly below the top rail of the TVP, and so did I, especially when I looked at how wide the T-Maxx battery box was, but it worked out perfect. I drilled a few holes in the bottom of the battery box to line up with the holes in the mount, and the flat bottom of the box keeps it in place well (just remember to use locktite on all screws where metal is on metal).

Put together, it looks like this:

Why a T-Maxx battery box, when there are so many other ones that are smaller? Well, I like the T-Maxx batt box because it holds everything, including a port on the top with a rubber plug that you use to recharge the battery pack. When you are done, pop the plug back in and there is no leakage of water, etc.

So now I have the battery moved, but I still need to move the receiver. This is where the Traxxas radio box comes in. Since my LHS pretty much carries only Traxxas and Losi, shopping the rack for parts is hit-or-miss, but this worked out well. I just toolk my spektrum receiver, velcro'ed it to the top of the case, routed the wires for the battery and servo.

I spent a bunch of time trying to figure out how to mount the box to the back, but decided on zip-ties - cheap, easy, and doesn't require me to drill holes or fab up crazy brackets.

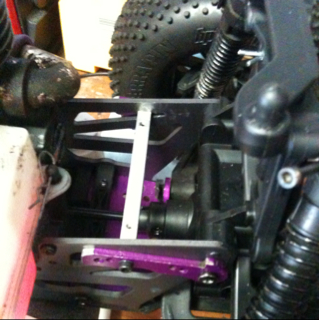

The finished product (still need to tuck wires)

Hope this helps someone!

Bob

Well today I started the first steps in the tank relocation, by moving the revceiver and battery to the back. This is also posted in the How-To section, but wanted to add it here too:

=======================================

OK, few caveats:

1) This is my first how-to, so be gentle

2) My truck is a Savage 25 with the XL TVP's - this gives me the room to move the battery box behind the motor - so I don't know if it will work for everyone

3) Where the battery is mounted will block your access it you use a roto-start - just keep that in mind.

So this is how I moved my receiver and battery from the front of the truck to the rear, in preparation for a mid-tank mod coming soon. My mission was to do it as cheap as I could using crap I had lying around as much as possible.

Parts List:

1) 2 aluminum bulkhead braces

2) 2 servo wire extensions

3) one T-Maxx battery box

4) one motor mount brace

5) one receiver box (Traxxas #4924 - no idea what it is out of)

To start things off, I needed to figure out how to mount a horizontal brace from TVP to TVP without drilling - I did not want to weaken the TVP at all, and it seemed there HAD to be a way to make this work.

When I lined up the brace between the TVP's, I saw that the spaces cut out where different from side to side, so I had to find a place on each side where they were the same. Once I did that, it should be a matter of putting something there to hold it in place - right?

After I found a place on both sides of the TVP's where I could attach the brace and keep it even, I needed a way to keep it from moving around too much - I happened to have a few diff braces lying around from my XL diff conversion, and I used them to hold the brace in place front to rear. All put together, it looks like this:

You will notice that the brace is significantly below the top rail of the TVP, and so did I, especially when I looked at how wide the T-Maxx battery box was, but it worked out perfect. I drilled a few holes in the bottom of the battery box to line up with the holes in the mount, and the flat bottom of the box keeps it in place well (just remember to use locktite on all screws where metal is on metal).

Put together, it looks like this:

Why a T-Maxx battery box, when there are so many other ones that are smaller? Well, I like the T-Maxx batt box because it holds everything, including a port on the top with a rubber plug that you use to recharge the battery pack. When you are done, pop the plug back in and there is no leakage of water, etc.

So now I have the battery moved, but I still need to move the receiver. This is where the Traxxas radio box comes in. Since my LHS pretty much carries only Traxxas and Losi, shopping the rack for parts is hit-or-miss, but this worked out well. I just toolk my spektrum receiver, velcro'ed it to the top of the case, routed the wires for the battery and servo.

I spent a bunch of time trying to figure out how to mount the box to the back, but decided on zip-ties - cheap, easy, and doesn't require me to drill holes or fab up crazy brackets.

The finished product (still need to tuck wires)

Hope this helps someone!

Bob