Just a bill

Member

- Messages

- 19

- Location

- Las vegas

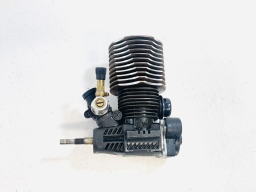

Hey guys I'm having trouble with the start shaft stripping I changed to the roto start from the pull start because it was just to hard to pull I think it has too much compression with no fuel in it once the glo plug is in I was able to pull the rope with my foot on the truck any time the motor turns over it fires up and really runs great so much power even with the wheelie bar it will flip itself over any time I nail the throttle and that's in loose dirt any advice on how to lower the comp.? Thanks