GRKSTL

Well-Known Member

- Messages

- 226

- Location

- Homer Glen, IL

Hi everyone, as some of you may know already I just purchased my Savage because I destroyed my X1 truggy bashing. I now have a dedicated bashing rig. I will be posting pictures here through the build and upgrades. Please feel free to comment, I would like to upgrade more parts in the beginning, but money is kind of tight right now.

Have fun.

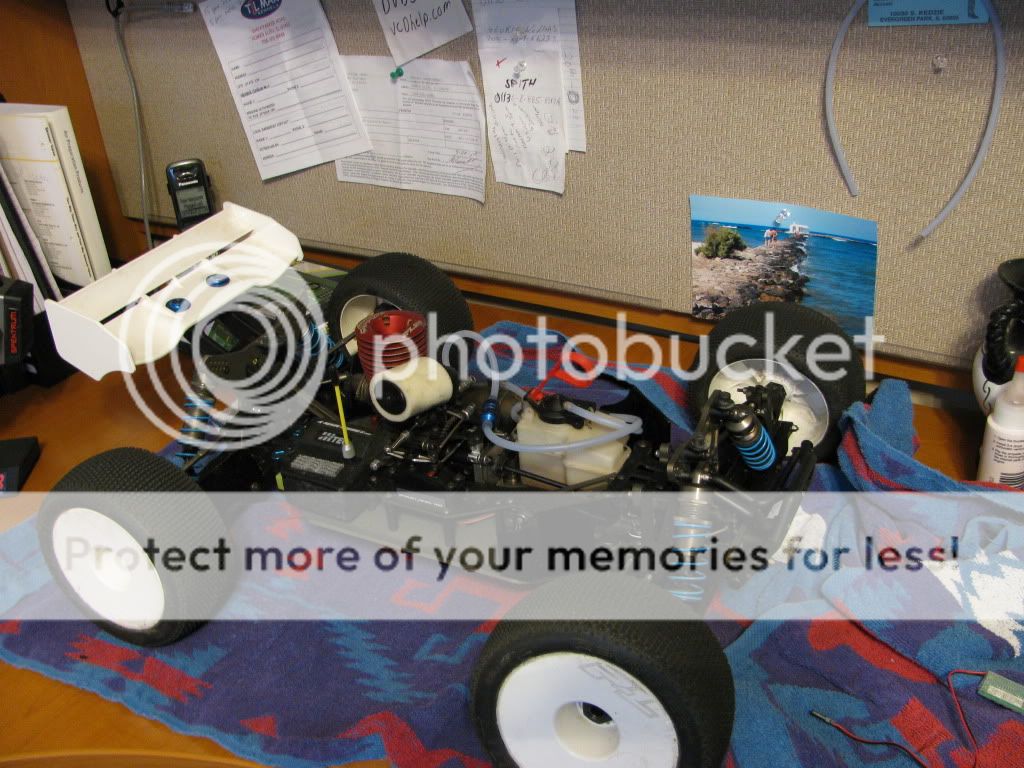

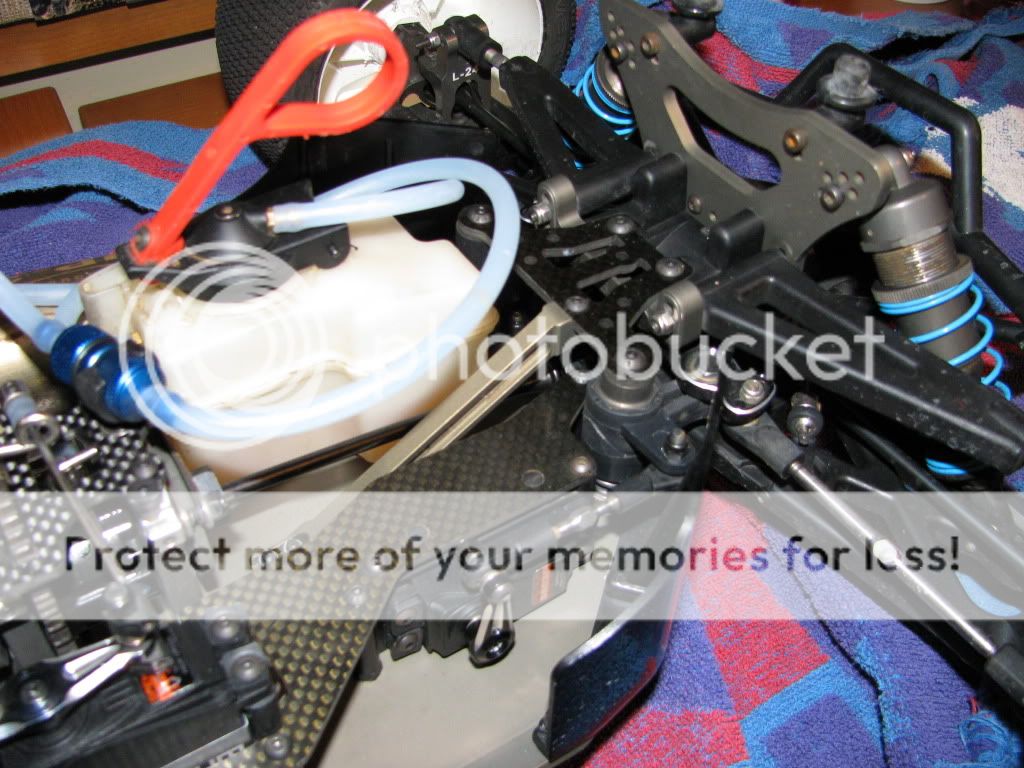

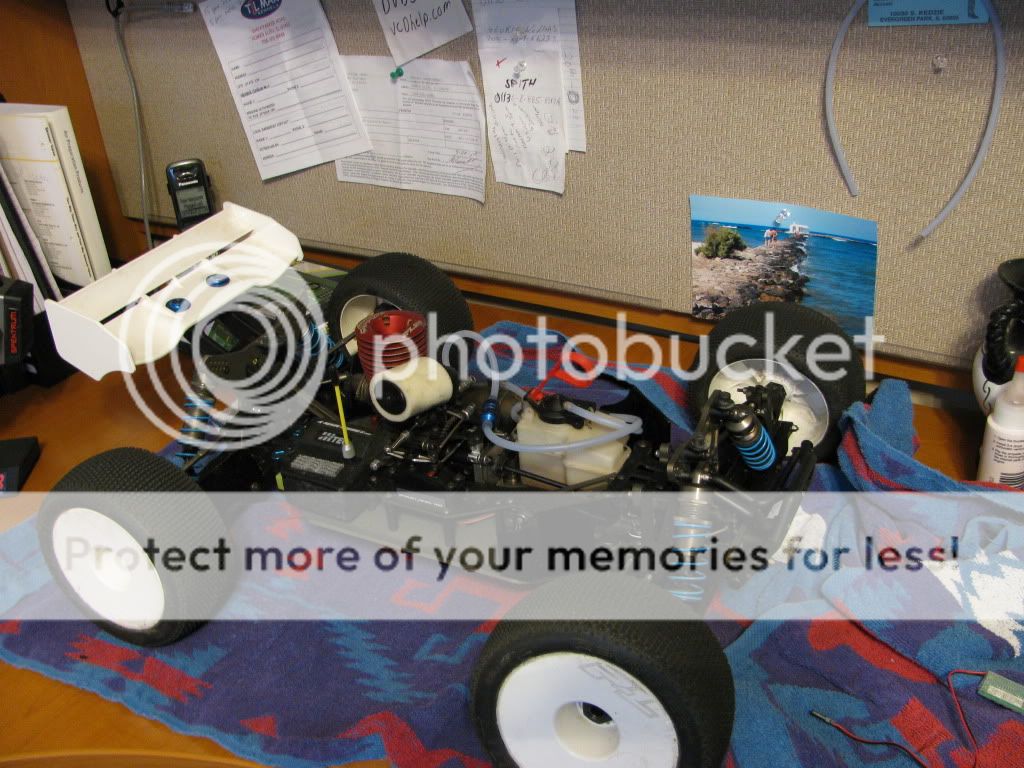

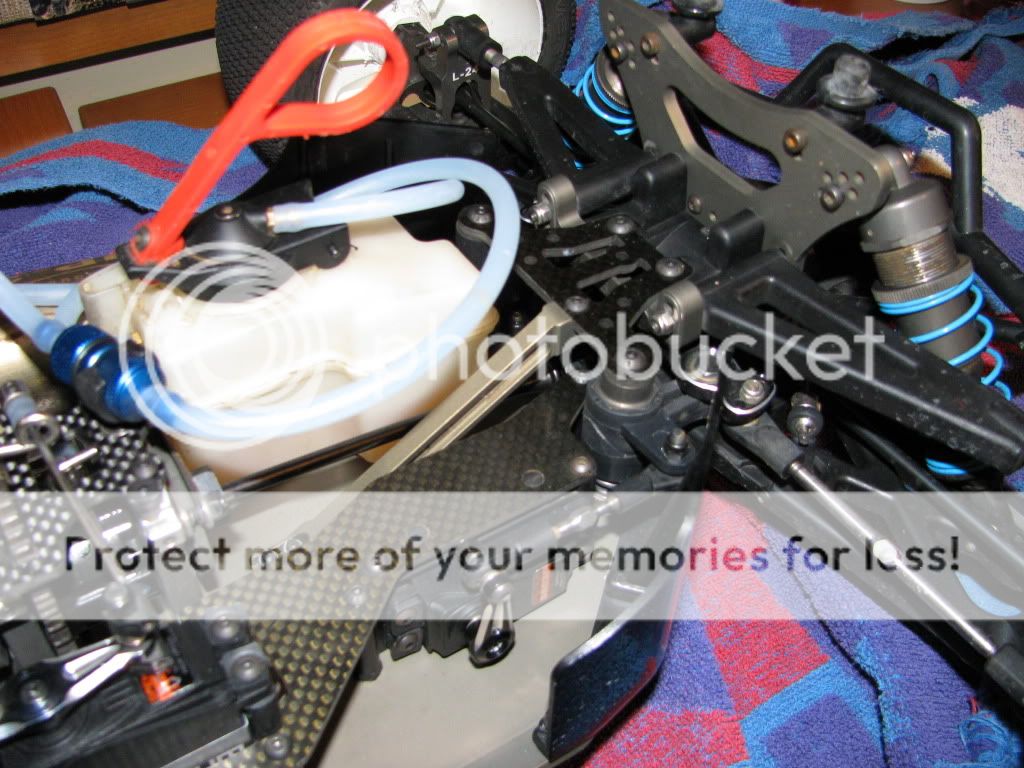

This is the truggy gettting a wipe down after putting it back together from parts I got from Nitrohouse.

Jammin 16mm Big bores shocks

Ready to go

But put on the shelf

FOR:

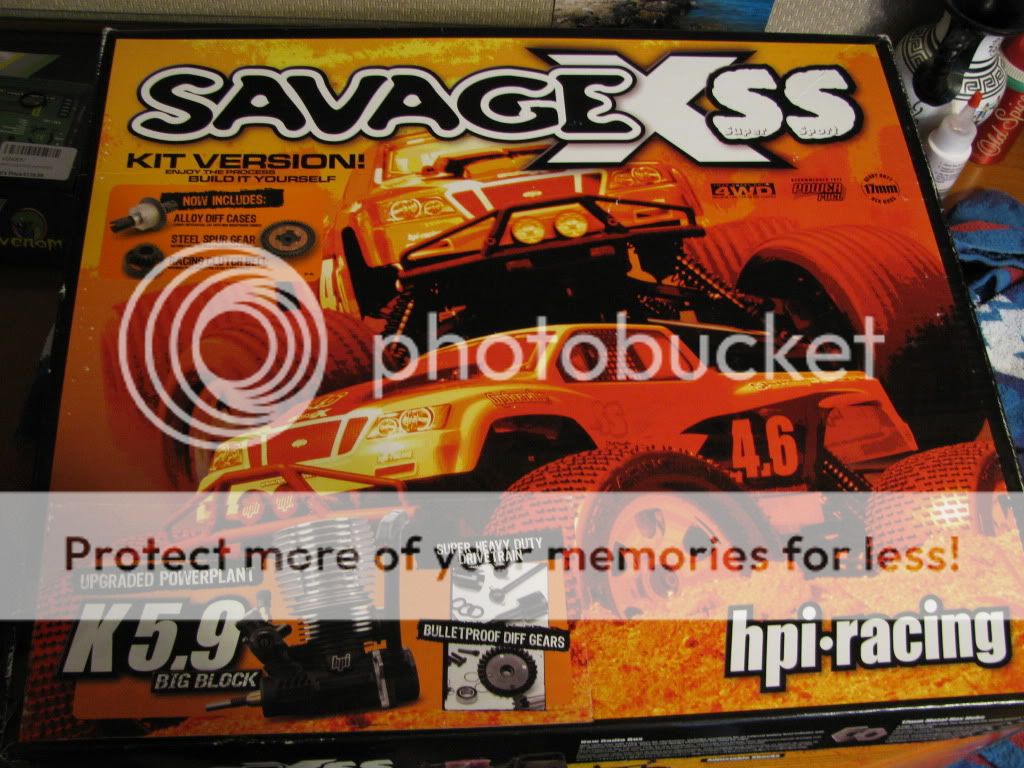

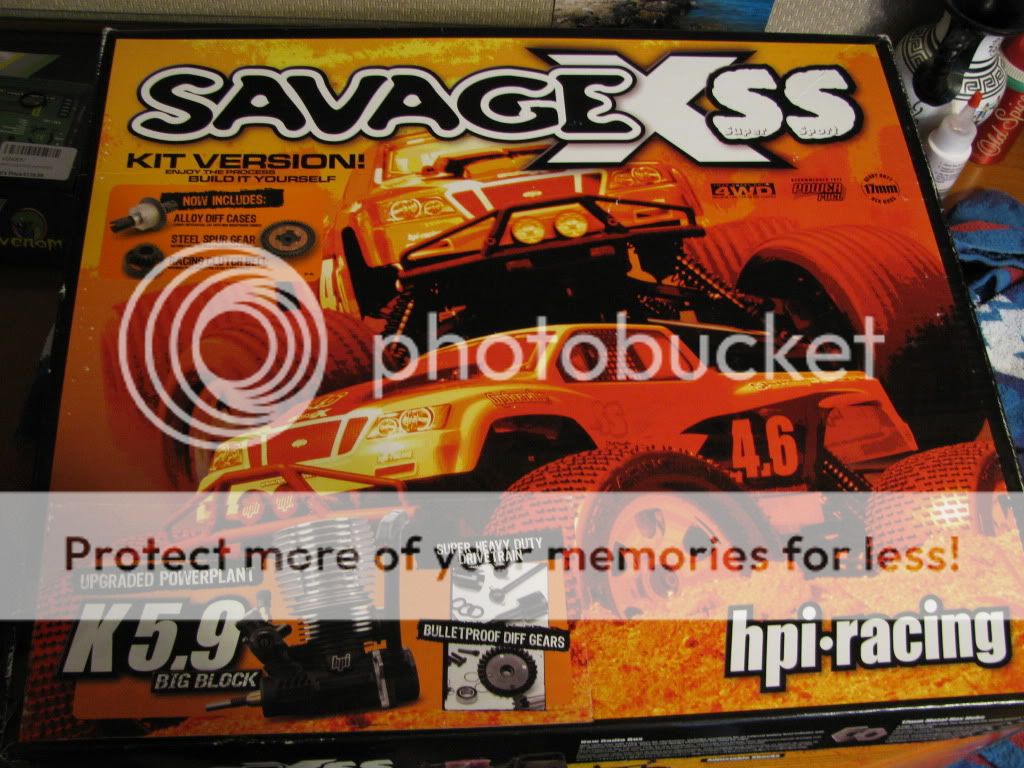

Looks like

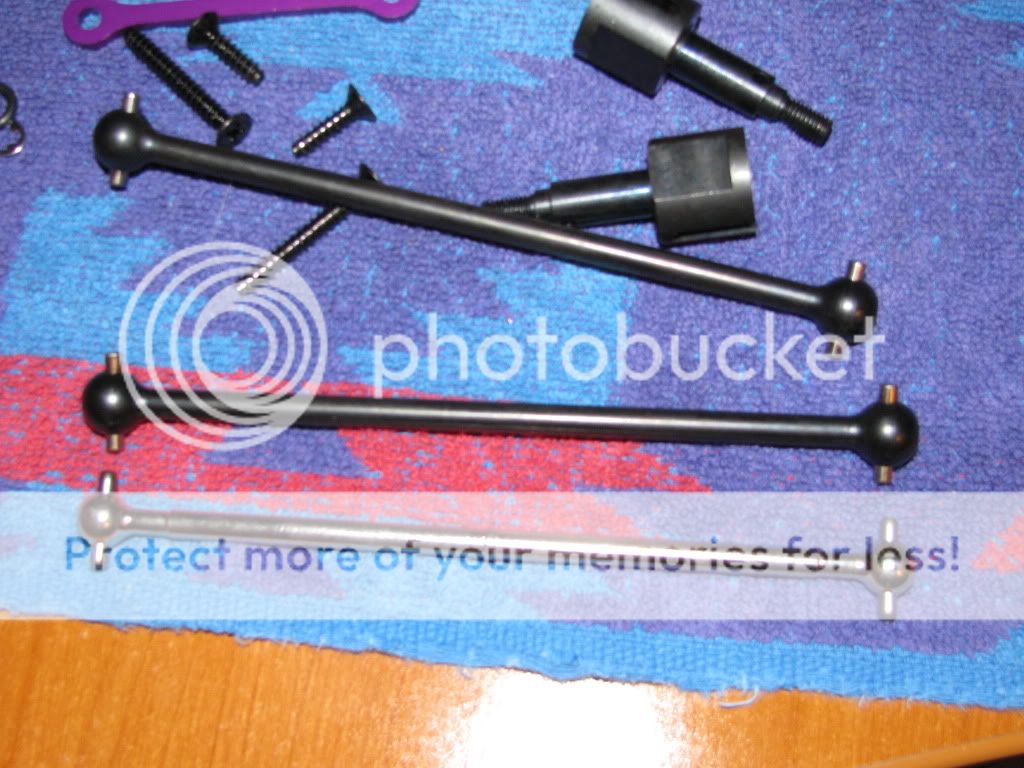

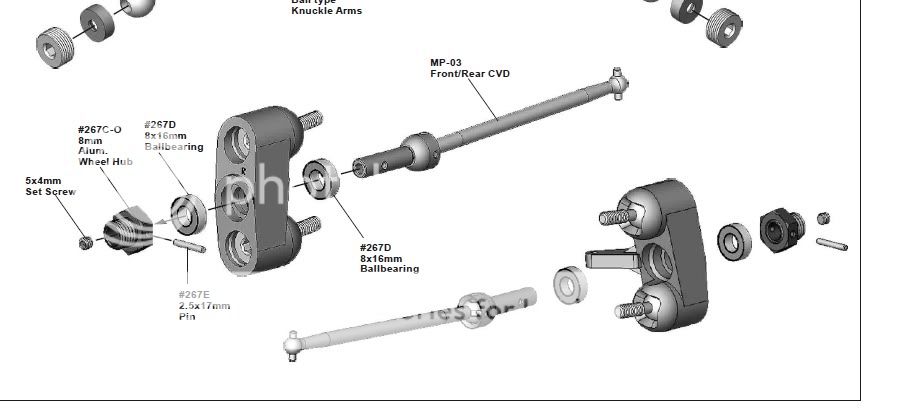

The diffs will need to be torn down and the upgrades need to be installed separately.

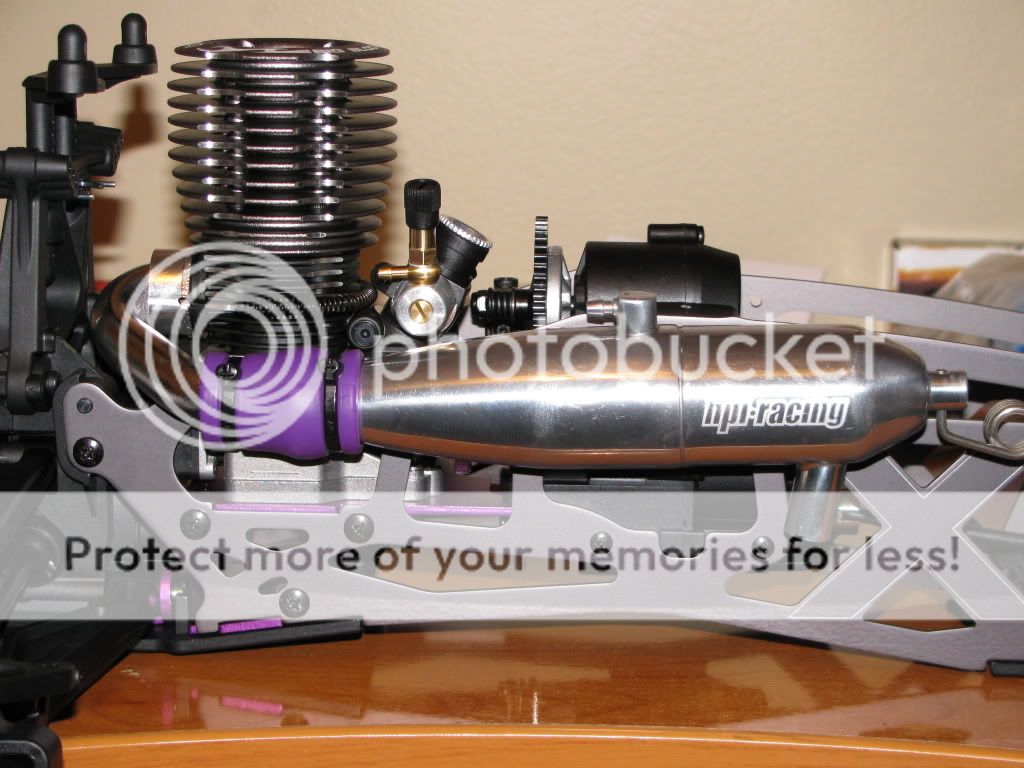

Going to stick with the 5.9 after seeing some YOU TUBE videos yesturday. But I will not put up with a pull start coming from bump boxes so I picked this up at my LHS today

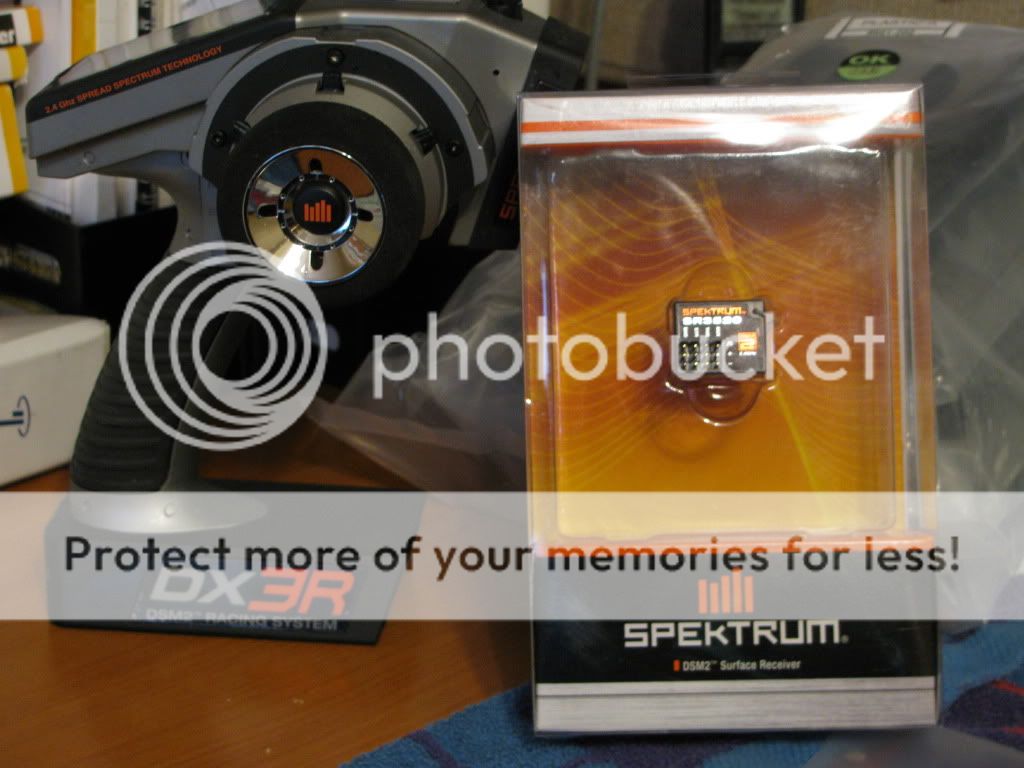

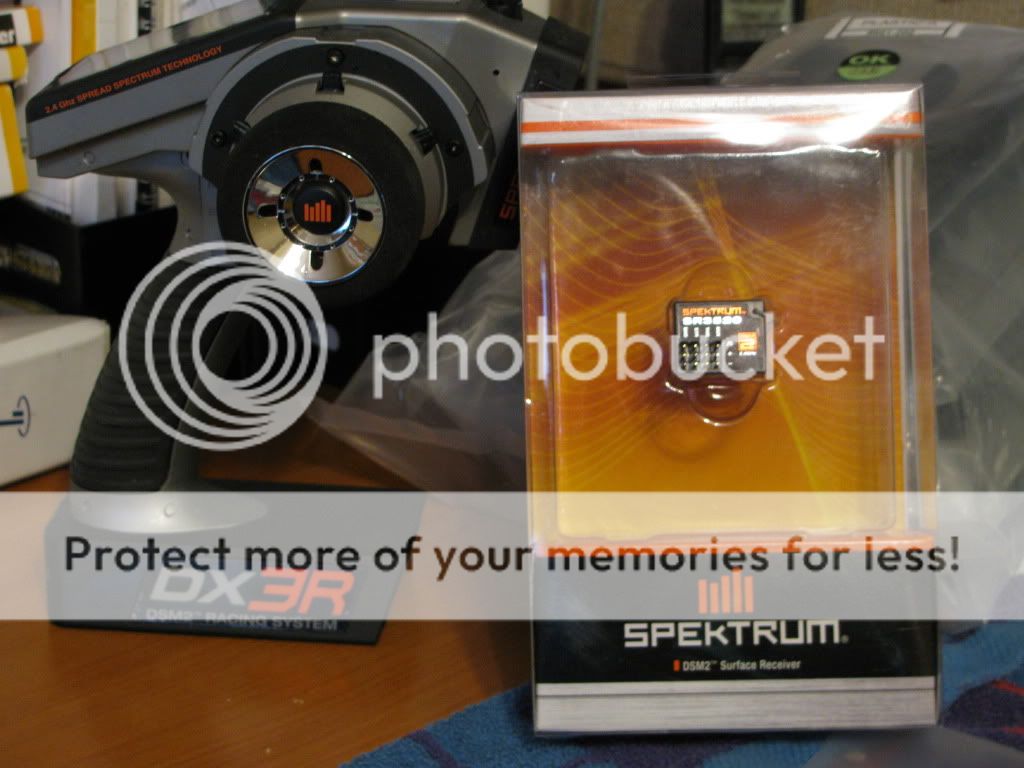

My reciever came in for my DX3R

Just wanted to throw these in here: pictures of the real race car sitting int he garage

She runs on the bottle

I will keep updating this thread, but due to New Years Eve, and plans to go out and party it up with the wife this will take a little time.

Bob

Have fun.

This is the truggy gettting a wipe down after putting it back together from parts I got from Nitrohouse.

Jammin 16mm Big bores shocks

Ready to go

But put on the shelf

FOR:

Looks like

The diffs will need to be torn down and the upgrades need to be installed separately.

Going to stick with the 5.9 after seeing some YOU TUBE videos yesturday. But I will not put up with a pull start coming from bump boxes so I picked this up at my LHS today

My reciever came in for my DX3R

Just wanted to throw these in here: pictures of the real race car sitting int he garage

She runs on the bottle

I will keep updating this thread, but due to New Years Eve, and plans to go out and party it up with the wife this will take a little time.

Bob

Last edited by a moderator: