MTBikerTim

Brushless Power!!!

- Messages

- 868

- Location

- Australia

I have been meaning to get this review done for a while now. It took me a while to get this clutch bell installed as I had to have my truck ready for racing and didn't have time to change the bell and setup shift points before I went racing. In the end I wish I had installed it before the race as it has made a big difference.

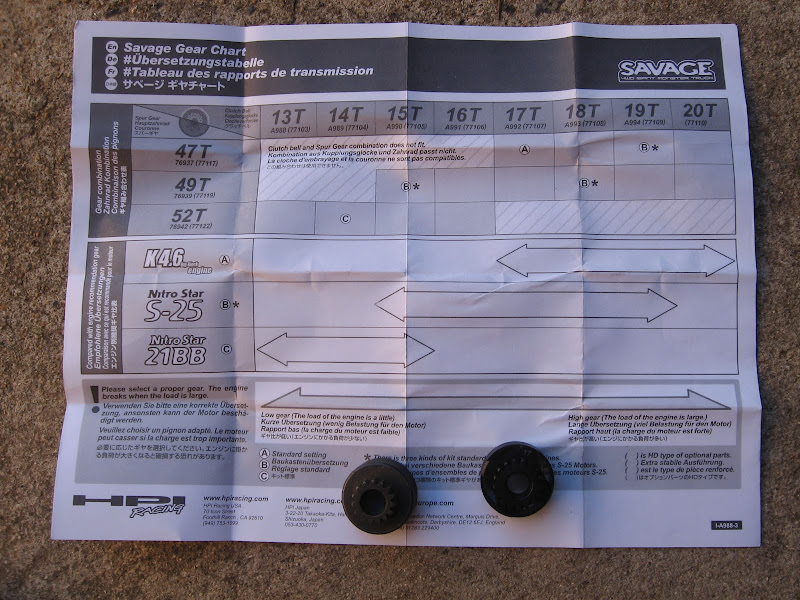

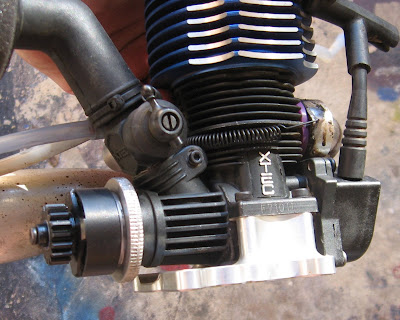

This is what was sent to me by Mega and I have to say a big thank you for letting me do this. Inside the pack you get 2 things. The 17t clutch bell and a gearing chart. The clutch bell in the picture on the left is my old HPI 15t clutch bell.

click for bigger picture

As you can see this is a very handy sheet to have. It has a lot more info on it then the one on the HPI website. Notice that all 3 spur gears are shown on this sheet.

Installation:

Installation wasn't as easy as I was expecting but this was due to my savage not the clutch bell. The clutch bell went onto the engine with out a problem. It was exactly the same dimensions as my old clutch bell so shimming did not change. While I was swapping the clutch bell I noticed my clutch bearings weren't spinning as freely as they used to so I put on a new set.

The problem came when I tried to put the engine back into the savage. The engine would not fit with a 17t clutch bell and 49t spur. This wouldn't be a problem on a standard savage but my savage has Fast Lane Machine chassis plates, engine plate and engine mount (the LRP back plate probably doesn't help much either). This seems to restrict my gearing options. I went back to the supplied gearing chart to see what I could do. This is when I noticed that the standard K4.6 is geared with a 17t pinion and a 47t spur. So I swapped out my 49t spur with the 47t spur and I could fit the engine and set the gear mesh correctly. The gear mesh was smooth as butter too, no noise at all. A few rocks will fix that though I am sure.

The final thing to do with the install was to adjust my shift points. Normally I would adjust these after seeing the car run but since I already had the top of the tranny off to change my spur I gave the 1st to second shift point screw a quarter turn in. I left the second to third shift point alone as it was changing too late on the old gear ratio.

Testing:

I mentioned I wished I had changed the clutch bell earlier. Well the reason was because with my old gearing my LRP .28 was making my savage incredibly difficult to drive at low speed. Giving just enough throttle to get the clutch to engage still caused all the weight to shift off the front wheels making it very difficult to make tight turns. I was also having temperature issues as my engine would run quite hot when running in an open area (WOT mostly) and cold on the race track (couldn't even get full throttle down the straight). My engine is now not revving as hard on WOT and I also have a lot more top speed. The bottom end is dulled down now to the point where it is still easy to pop wheelies but the car doesn't sit down onto the back wheels as much making it handle much better.

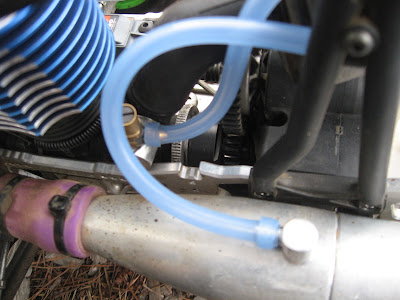

The venting probably helps with cooling the clutch shoes but it is very difficult to test. I found both the old clutch bell and new one seemed to stay around the same temperature as the engine in that area. The really good thing about the venting though is the easy inspection of the clutch shoes without taking off the clutch bell. For someone like me who is naughty and didn't check my clutch shoes barely at all, I can now check them with ease.

Durability/Quality:

I have only run this clutch bell a few times so I can't say for sure how well it will hold up. What I can say though is that if it is anything like the HPI 15t clutch bell I used it will hold up no problems. You can see my old clutch bell in the pictures on the left. A nice touch on the new clutch bell is the 17t printed on the bell. A lot easier to read that then trying to count teeth. The 17t is also indented so it shouldn't wear off in a hurry.

I have been running my old clutch bell for years now and it is still perfect. I have always run plastic spurs which definitely helps the clutch bell last a lot longer. I have also been fairly diligent in removing the tiny rocks that get embedded in the spur gear and do lots of damage to pinions.

My only complaint with this clutch bell is that there are small bits of metal left in between the teeth and clutch bell from machining the teeth. It is difficult to make out in this picture but it can be seen. They shouldn't effect the clutch bell performance at all so I didn't try to remove them as it would most likely make it worse.

Pros:

Reliable

Perfect fit

Easy inspection of clutch shoes

very smooth gear mesh

Cons:

Small machining scrap left between teeth and clutch bell

Final score: 8/10

Looses points for small machining left overs but other then that it does it's very job well.

This is what was sent to me by Mega and I have to say a big thank you for letting me do this. Inside the pack you get 2 things. The 17t clutch bell and a gearing chart. The clutch bell in the picture on the left is my old HPI 15t clutch bell.

click for bigger picture

As you can see this is a very handy sheet to have. It has a lot more info on it then the one on the HPI website. Notice that all 3 spur gears are shown on this sheet.

Installation:

Installation wasn't as easy as I was expecting but this was due to my savage not the clutch bell. The clutch bell went onto the engine with out a problem. It was exactly the same dimensions as my old clutch bell so shimming did not change. While I was swapping the clutch bell I noticed my clutch bearings weren't spinning as freely as they used to so I put on a new set.

The problem came when I tried to put the engine back into the savage. The engine would not fit with a 17t clutch bell and 49t spur. This wouldn't be a problem on a standard savage but my savage has Fast Lane Machine chassis plates, engine plate and engine mount (the LRP back plate probably doesn't help much either). This seems to restrict my gearing options. I went back to the supplied gearing chart to see what I could do. This is when I noticed that the standard K4.6 is geared with a 17t pinion and a 47t spur. So I swapped out my 49t spur with the 47t spur and I could fit the engine and set the gear mesh correctly. The gear mesh was smooth as butter too, no noise at all. A few rocks will fix that though I am sure.

The final thing to do with the install was to adjust my shift points. Normally I would adjust these after seeing the car run but since I already had the top of the tranny off to change my spur I gave the 1st to second shift point screw a quarter turn in. I left the second to third shift point alone as it was changing too late on the old gear ratio.

Testing:

I mentioned I wished I had changed the clutch bell earlier. Well the reason was because with my old gearing my LRP .28 was making my savage incredibly difficult to drive at low speed. Giving just enough throttle to get the clutch to engage still caused all the weight to shift off the front wheels making it very difficult to make tight turns. I was also having temperature issues as my engine would run quite hot when running in an open area (WOT mostly) and cold on the race track (couldn't even get full throttle down the straight). My engine is now not revving as hard on WOT and I also have a lot more top speed. The bottom end is dulled down now to the point where it is still easy to pop wheelies but the car doesn't sit down onto the back wheels as much making it handle much better.

The venting probably helps with cooling the clutch shoes but it is very difficult to test. I found both the old clutch bell and new one seemed to stay around the same temperature as the engine in that area. The really good thing about the venting though is the easy inspection of the clutch shoes without taking off the clutch bell. For someone like me who is naughty and didn't check my clutch shoes barely at all, I can now check them with ease.

Durability/Quality:

I have only run this clutch bell a few times so I can't say for sure how well it will hold up. What I can say though is that if it is anything like the HPI 15t clutch bell I used it will hold up no problems. You can see my old clutch bell in the pictures on the left. A nice touch on the new clutch bell is the 17t printed on the bell. A lot easier to read that then trying to count teeth. The 17t is also indented so it shouldn't wear off in a hurry.

I have been running my old clutch bell for years now and it is still perfect. I have always run plastic spurs which definitely helps the clutch bell last a lot longer. I have also been fairly diligent in removing the tiny rocks that get embedded in the spur gear and do lots of damage to pinions.

My only complaint with this clutch bell is that there are small bits of metal left in between the teeth and clutch bell from machining the teeth. It is difficult to make out in this picture but it can be seen. They shouldn't effect the clutch bell performance at all so I didn't try to remove them as it would most likely make it worse.

Pros:

Reliable

Perfect fit

Easy inspection of clutch shoes

very smooth gear mesh

Cons:

Small machining scrap left between teeth and clutch bell

Final score: 8/10

Looses points for small machining left overs but other then that it does it's very job well.

Last edited by a moderator: