Piccions93

Active Member

- Messages

- 58

- Location

- Italy

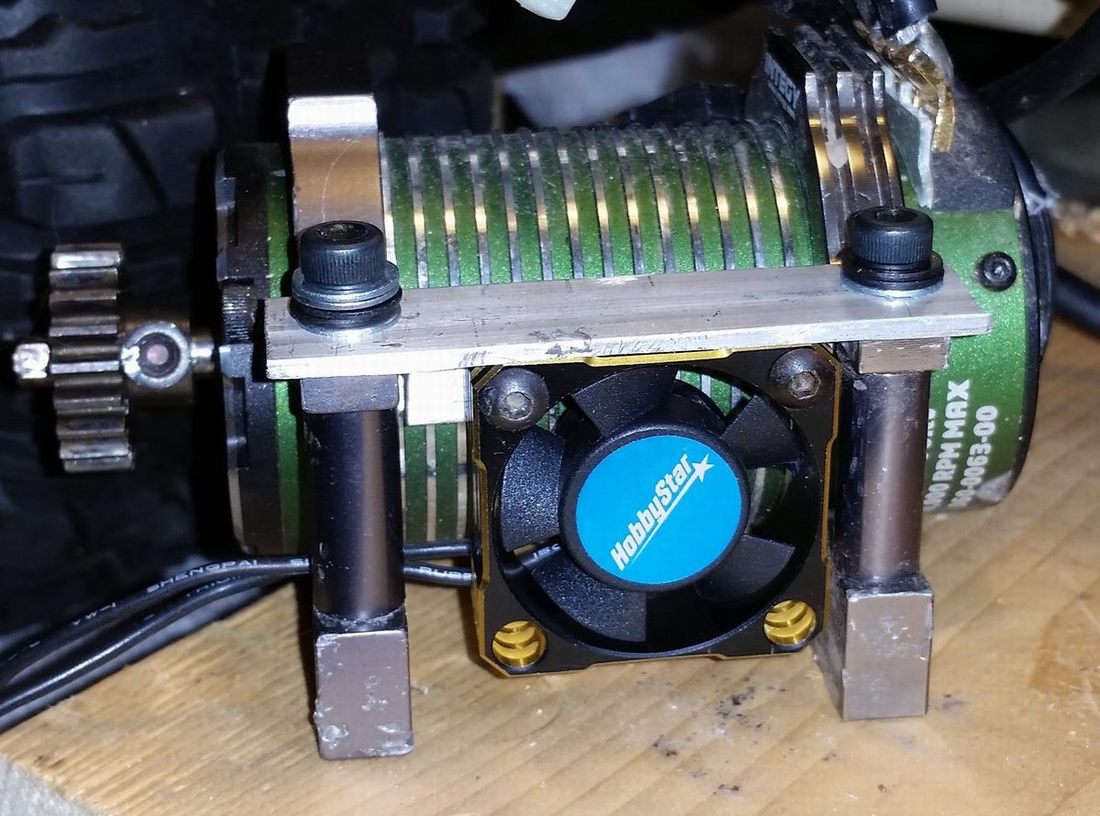

Hi guys, i'd like to put a cooling mount on my savage flux xl, that runs the original Tork 2200 kv motor. Do you have any ideas on what is best to buy? Thank you!

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Welcome to HPISavageForum, a friendly forum to discuss the Savage RC Truck.

Your voice is missing! You will need to register to get access to the following site features:We hope to see you as a part of our community soon!