pelicanprentice

Active Member

- Messages

- 107

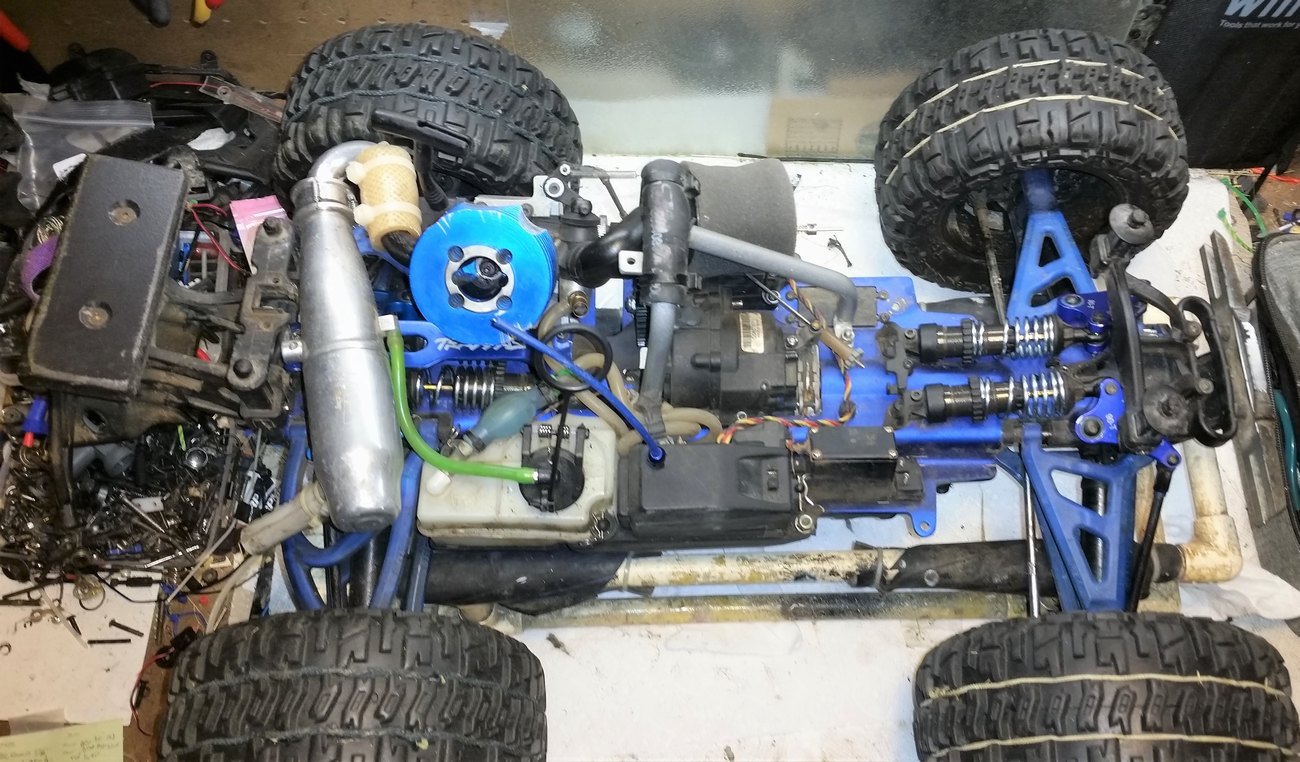

hello, i have a savage x 4.6 and i recently got the hpi aluminum tuned pipe because my old plastic pipe broke. i have it connected to the header with a silicome coupler but i have some doubts on the coupler that it leaks etc, i feel like the coupler is too long and that my header and pipe arent sealed to the best of there ability. i have seen that some better pipes have some type of screw on or metal coupler that they use.

do you guys know of any coupler that i can use on my pipe to replace the silicone coupler?

thx

do you guys know of any coupler that i can use on my pipe to replace the silicone coupler?

thx